Investing in Xiamen Public Number focuses on the scientific and technological achievements of Jia Hydrogen, which has been rated as an international leader! A Xiamen enterprise has formed an original hydrogen catalytic technology system

2024-08-02

The chemical industry is one of the most widely used areas of hydrogen And from hydrogen production, hydrogen storage to hydrogen use, Catalysts are key. Therefore, the catalyst is also known as the "chip" of the chemical industry ".

The chemical industry is one of the most widely used areas of hydrogen,

And from hydrogen production, hydrogen storage to hydrogen use,

Catalysts are key.

Therefore, the catalyst is also known as the chemical industry."The Chip".

Aiming at this field, Kah Keng Innovation LabFrom 2022 onwards, the planning and layout of high-selectivity catalyst development and industrial application projects, based on non-contact hydrogenation core catalytic technology to develop a series of continuous hydrogenation catalysts, hatched the establishment of Xiamen Jiaxing Technology Co., Ltd. (hereinafter referred to as Jiaxing Technology).

At present, Jia hydrogen technology in hydrogen production(electrolyzed water)Hydrogen storage(ammonia hydrogen storage)and with hydrogen(Catalytic Hydrogenation and Hydrogen Fuel Cells)The whole industry chain, has formed an original hydrogen catalytic technology system, to provide a complete catalytic technology package solutions.

deep tillage continuous hydrogenation catalysis

deep tillage continuous hydrogenation catalysis

In the laboratory of Jiageng Technology, three fixed-bed continuous hydrogenation catalytic units continue to operate. Liu Shengjie, head of the high-selectivity catalyst project of Jiageng Innovation Laboratory and executive director of Jiageng Technology, is guiding the students to operate and test and evaluate the performance of the catalyst.

This device in front of me

It is built with reference to industrial production devices.

Introduction by Liu Shengjie

The high selectivity of the catalyst means that there are few impurities and by-products in the catalytic process, the cost and energy consumption are reduced, and the product purity is higher and the quality is better. At present, the continuous hydrogenation catalyst developed by the laboratory has reached the domestic leading level.

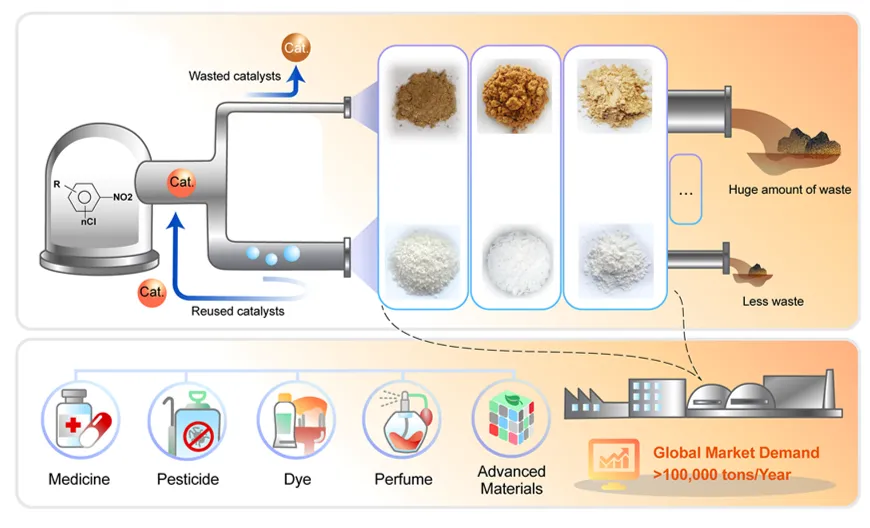

After the catalyst is filled in, the equipment operates automatically, and the product is released while the raw material is fed in, so it is called continuous hydrogenation catalysis. Compared with the traditional batch process, continuous hydrogenation catalytic technology is a process with high production efficiency, stable product quality, constant and easy control of reaction conditions, and has the advantages of environmental protection, energy saving and self-control.

Application Cases of High Selectivity Industrial Catalyst for Improving Quality and Efficiency

Continuous Hydrogenation Catalytic Technology

Continuous Hydrogenation Catalytic Technology

From the Zheng Nanfeng team of Xiamen University“non-contact hydrogenation”The core concept of basic research subverts the traditional cognition that the raw material must be in direct contact with the active metal atom of the catalyst at the molecular scale in order to have a catalytic reaction. Based on the second prize of the National Natural Science Award and the key achievements of the national key R & D plan project, the project R & D team continuously optimizes the design of the catalyst structure through the control of the surface interface structure, thereby greatly improving the catalytic selectivity and life, and continuously reducing the amount of precious metals in the catalyst. High selectivity, low cost, high quality, low energy consumption, green and low carbon and other comprehensive advantages.

Innovative catalyst design concept and continuous process, promote the application of enterprises to continuously upgrade the technical route, from the source to avoid the generation of three wastes, and achieve unprecedented new performance, enabling the fine chemical and new materials industry high-quality development.

Explore new areas, new scenarios and applications

Explore new areas, new scenarios and applications

Jiaxin Technology continues to focus on the development and application of highly selective hydrogen catalytic technology, using highly selective catalysts to convert hydrogen into high-value chemicals and new materials. InFrom 2017 to 2022, the project team cooperated with the company to build 8 new production lines, and more than a dozen products have been used in industry. Incubation for just over a year yielded substantial gains.

Liu Shengjie said

We must truly promote the synergy of innovation chains, industrial chains, capital chains, and talent chains in the fields of hydrogen energy and chemicals, so that innovation results can be transformed into real productivity.

At present, the continuous hydrogenation catalytic technology of the project team has been selected into the first batch of technical product catalogues encouraged by the petrochemical and chemical industry of the Ministry of Industry and Information Technology, and the relevant catalysts have begun to realize the continuous industrial production of 10,000 tons of key new materials, which has increased the cumulative output value of the application enterprises.10Billions of dollars.

The clean hydrogenation catalytic process replaces the traditional process of high pollution and high energy consumption, which can make the industrialThe "three wastes" will reduce emissions by 95% and realize the high-end intelligent development of the application industry. More importantly, high selectivity catalyst is one of the key technologies to break the low-end surplus and high-end shortage of high-performance new materials industry.

Introduction by Liu Shengjie

Through the original high selective hydrogenation catalytic technology, it can greatly improve the monomer purity of a variety of new materials, reduce their production costs, and cultivate new quality productivity in the new materials industry.

Today, the project team's technology has been successfully applied to the production of new materials such as aramid fibers and polyimides.

This yearIn April, the scientific and technological achievement of "key technology development and industrialization of hexanediamine high quality by caprolactam method", which was completed by Jiaxin science and technology project team, was identified as an international leader by industry experts of China Petroleum and Chemical Industry Federation. At present, the project has built the world's first 10,000-ton caprolactam-based hexamethylene diamine production plant, stably producing superior hexamethylene diamine and nylon 66 products, filling the gap in the production technology of hexamethylene diamine high quality by caprolactam-based production.

Application Case of MW PEM Electrolytic Water Hydrogen Production System

At present, Jiaxing Technology has independently developed low-cost electrolysis water hydrogen production catalyst, low-temperature ammonia decomposition hydrogen production catalyst, high-selectivity industrial hydrogenation catalyst and hydrogen fuel cell catalyst, initially constructed hydrogen catalyst ecology, formed a series of technology systems at the two major industrial ends of hydrogen industry and hydrogen energy, and strived to become a new generation of hydrogen catalytic technology overall solution service provider.

Editor: Investing in Xiamen Planning: Xiamen Investment Promotion Office.

Content Source: Xiamen Daily Reporter: Wu Junning Correspondent: Yang Guoning Huang Yanan, photo source: Xiamen Daily, Jiageng Innovation Laboratory, editor: Tian Yu Audit: Yang Jiayin, copyright owned by the original creator.

Copyright Statement: Unless it cannot be confirmed, we will indicate the author and source. If there is any infringement, please let us know and we will delete it immediately and apologize. Thank you!

Artikel sebelumnya

Blog terkait

Hubungi kami

Situs web: Website

Alamat: No. 66 jalan selatan Xinyuan, distrik Haicang, Kota Xiamen, Provinsi Fujian, Tiongkok

Kode QR akun resmi